As it pertains to retro reflective tape, there are several factors that we consider when reviewing an accident between a large semi-truck and another vehicle. Our goal in assessing these elements is to estimate what an approaching vehicle most likely saw as they neared the truck in question. This can be compared and contrasted with a properly marked truck.

These elements are as follows –

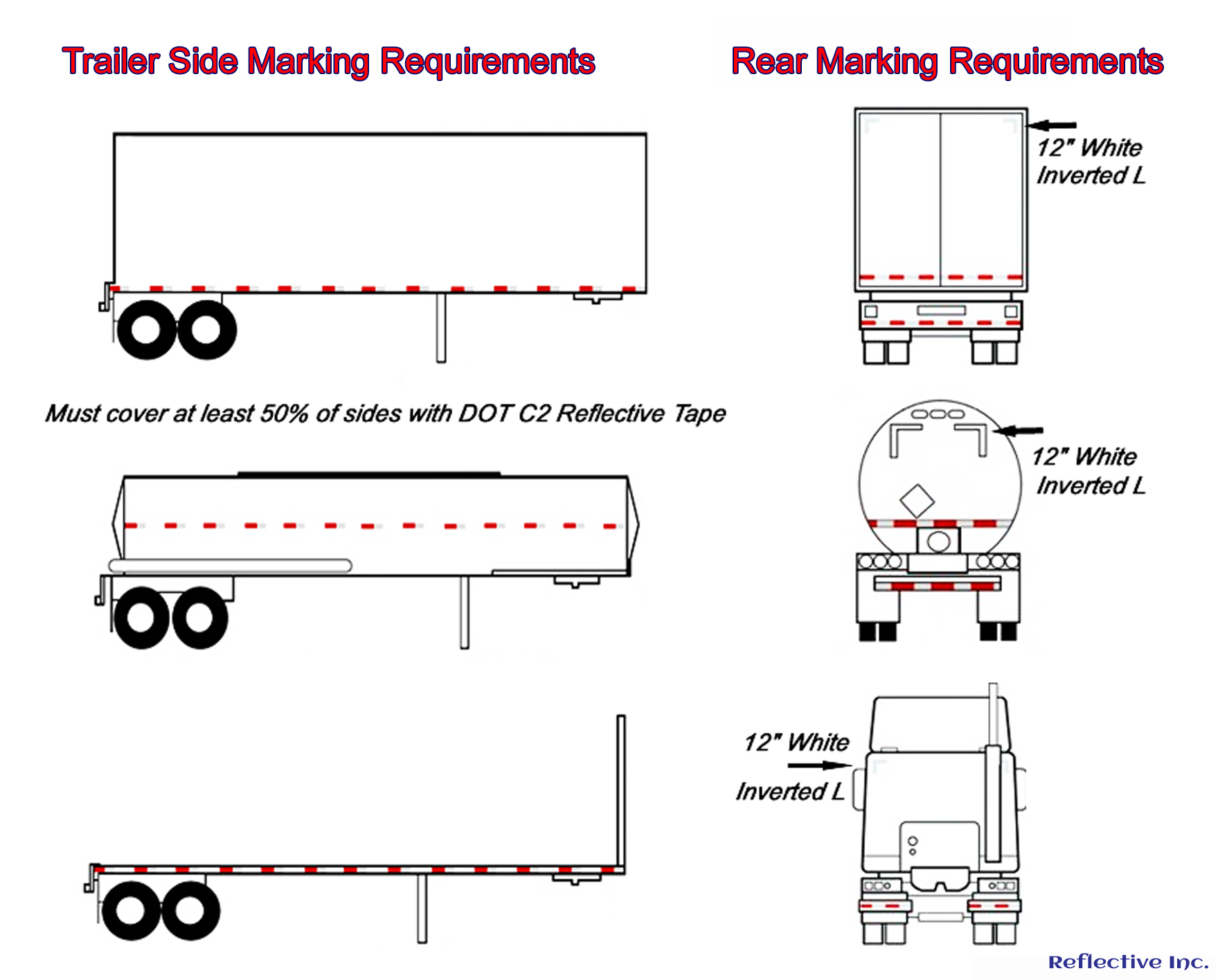

Properly Applied Certified Retro Reflective DOT C2 Tape – It important that certified reflective DOT tape with the DOT-C2 logo be affixed to a semi truck and the trailer it tows, in the right amounts, and in the proper places. Failure to do this violates Federal Regulation and places the lives of other drivers in danger. In dark conditions, the retro reflective tape on a truck may be the only thing that alerts a driver to a trucks presence. With this being said, the Federal Motor Carriers Safety Administration (FMCSA) and the National Highway Traffic Safety Administration (NHTSA) mandate that trucks over 80 inches wide and over 10,000 pounds be marked with DOT-C2 C3 or C4 retro reflective tape. (the C2 C3 C4 are the widths of the tape) Specific requirements are in our FMCSA article here.

To be certified, DOT tapes must meet certain requirements. These are color (chromaticity), surface appearance, width, pattern spacing, DOT-C2 logo, and retro reflective performance. Generally speaking, the regulation requires DOT tape to meet ASTM D4956 Type 5 specifications for all aspects of the film except for photo metrics. For photo-metrics, which in this case is brightness, the FMCSA provides a chart, however, it is roughly the equivalent of ASTM D4956 Type 3 requirements.

The amount of tape to be applied and where it must be applied are also specifically outlined in the Federal regulation. These areas are the sides of the trailer, the back lower areas, the back upper areas, and the truck itself (cab). All areas specified must be marked with DOT approved retro reflective tape that is a minimum of 2 inches wide, up to 4 inches. Damaged tape that no longer meets DOT specs may cause a truck to fail inspection.

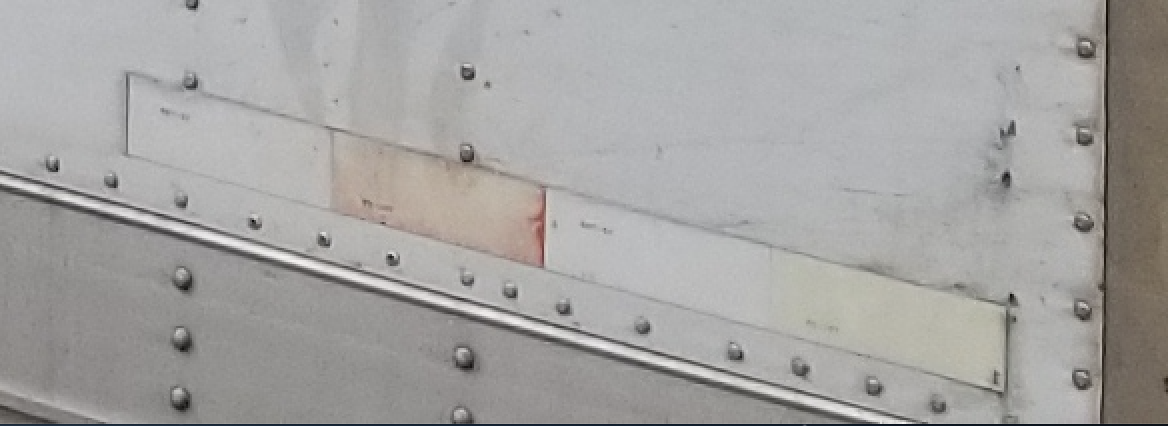

Condition of the DOT C2 Retro Reflective Tape – Damaged or missing retro reflective DOT C2 tape can affect the ability of other drivers to see a large truck at night. Tape age, weathering, dirt, and grime also contribute to a less effective reflective tape performance. Missing tape is often caught by DOT inspectors, but weathered, aged, or dirty tape are seldom used as grounds for an inspection failure since inspectors do not normally run retro reflectivity tests on the tape. But just because a truck did not fail an inspection, does not mean that the retro reflective tape on that truck is performing to minimum specifications.

In reference to age, DOT tape manufacturers warranty their tapes meet minimum FMCSA and NHTSA standards for 5 , 7 , or 10 years depending on the brand and model. And this warranty applies only if the tape is properly applied and cared for. After the warranty period expires, manufacturers no longer guarantee that the tape will meet minimum reflectivity requirements, which is the most important characteristic of the tape when it comes to sight distance. This means that it is possible that older tapes that are beyond their warranty no longer meet minimum reflectivity standards, and as such, no longer provide the necessary protection from collisions.

The issue with degraded tape is that as reflectivity decreases, the distance at which the tape can be seen decreases as well. So at some point, by the time a driver sees the tape, it is too late to stop, and a collision occurs.

Ambient Lighting at the Time of the Accident – Since light creates what our eyes see, it is very important to know how much light was present at the scene of an accident, at the exact time that it occurred. Was it day or night? Was the moon full? Were there street lights nearby? Or was it completely dark? This analysis is important because the less ambient light there is lighting up a truck, the more approaching drivers must depend on other conspicuity that is affixed to the truck itself. At night, with very little or no ambient lighting, approaching drivers depend solely on the large truck and trailers lights, and the retro reflective conspicuity tape attached to the truck itself. At night, without these two elements, or if they are substantially diminished, trucks can easily be invisible to an approaching driver.

Weather Conditions at the Time of the Accident – Rain, Snow, Fog, or Smoke in the area of an accident can affect visibility. Any one of these elements can greatly affect what an approaching driver sees as he nears a large semi truck. Darkness, and the addition of one or more of these elements can make perceiving objects in the distance difficult for a driver. In situations like this, effective truck lights, and bright retro reflective tape in very good condition would be necessary to cut through these elements and alert an approaching driver of the presence of a semi truck. In inclement conditions, even a moderately degraded film may not be enough to provide conspicuity, and as such, it is entirely possible that a large truck may appear invisible to an approaching driver.

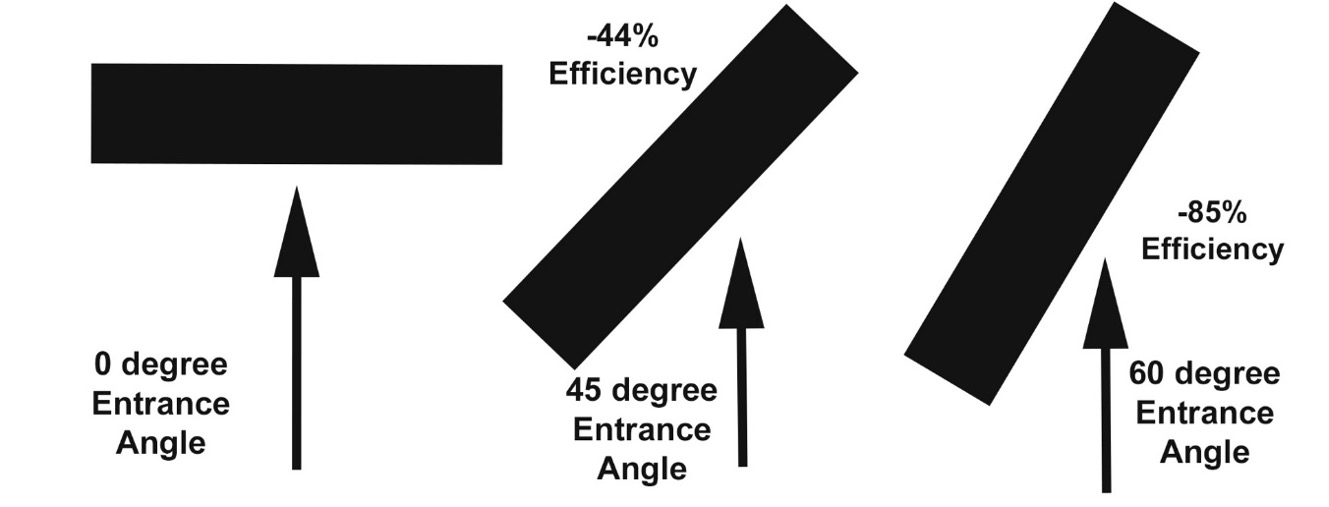

Angle of the Retro Reflective Tape in Relation to the Oncoming Driver (Entrance Angle of Light) – Retro Reflective Tapes perform at their maximum when they are perpendicular to a cars headlights. As that angle increases, and light from a cars headlights strike the tape at more and more of an angle, reflectivity decreases. At some point above the 45 degree mark, the tape no longer returns sufficient light to be seen from a distance. This angle can be created from a truck sitting at an angle across a roadway, or from the tape being applied at an angle on the truck. More often the issue is the overall angle of the truck. So if a truck is parked across a roadway at a 60 degree angle, an approaching vehicle may not see the retro reflective tape at all, even when close in. So if at night, a truck driver places his trailer at a sharp angle to approaching traffic, the chances of a collision are high since that sharp of an entrance angle renders reflective tape almost invisible.

Height of the Installed Retro Reflective Tape in Comparison to the Approaching Vehicles Headlights – The height DOT C2 retro reflective tape is applied is important. As stated in Federal Regulation, DOT C2 tape applied to the side of a truck should fall between 15 and 60 inches from the road surface. The main issue is height. Tape placed too high on a truck can result in car headlights (low beams) hitting below the tape. This is especially true with newer cars with a tight beam pattern. If a cars headlights hit below the conspicuity tape, very little light is returned to the driver, rendering the truck difficult for the driver to see. Generally, the lower that a tape can be installed on the sides of a truck, the better for visibility.

Competitive Lighting at the Accident Scene – At night, light coming from headlights, running lights, street lights, and other sources, compete with retro reflective tape for the attention of drivers. For example, if a section of Retro Reflective DOT tape, that reflects at 700 candelas, is near headlights that emit 15,000 to 20,000 candelas, it is easily drowned out. And if attention is drawn to the headlights of a truck, and its trailer is in the path of the oncoming vehicle, an accident can easily occur.

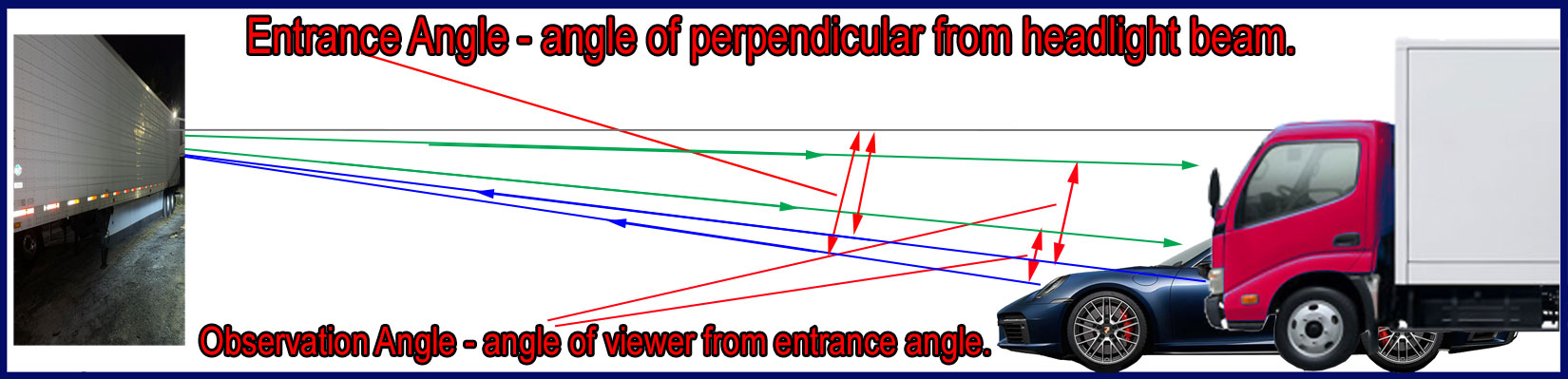

Observation Angle of Oncoming Driver To Returning Light – The distance that a drivers eyes are from their own headlights constitutes what is known as the observation angle. Light from headlights is directed at retro reflective tape and is bounced back to the source of the light which is the headlights. In a standard vehicle, the eyes of the driver are only slightly above the returning light. In a truck however, the eyes of the driver are higher. The typical observation angle for the driver of a car is .20 degrees, and the observation angle for a truck driver is .50 degrees. This difference in observation angles reduces the return of light to a drivers eyes by a surprising 77%.

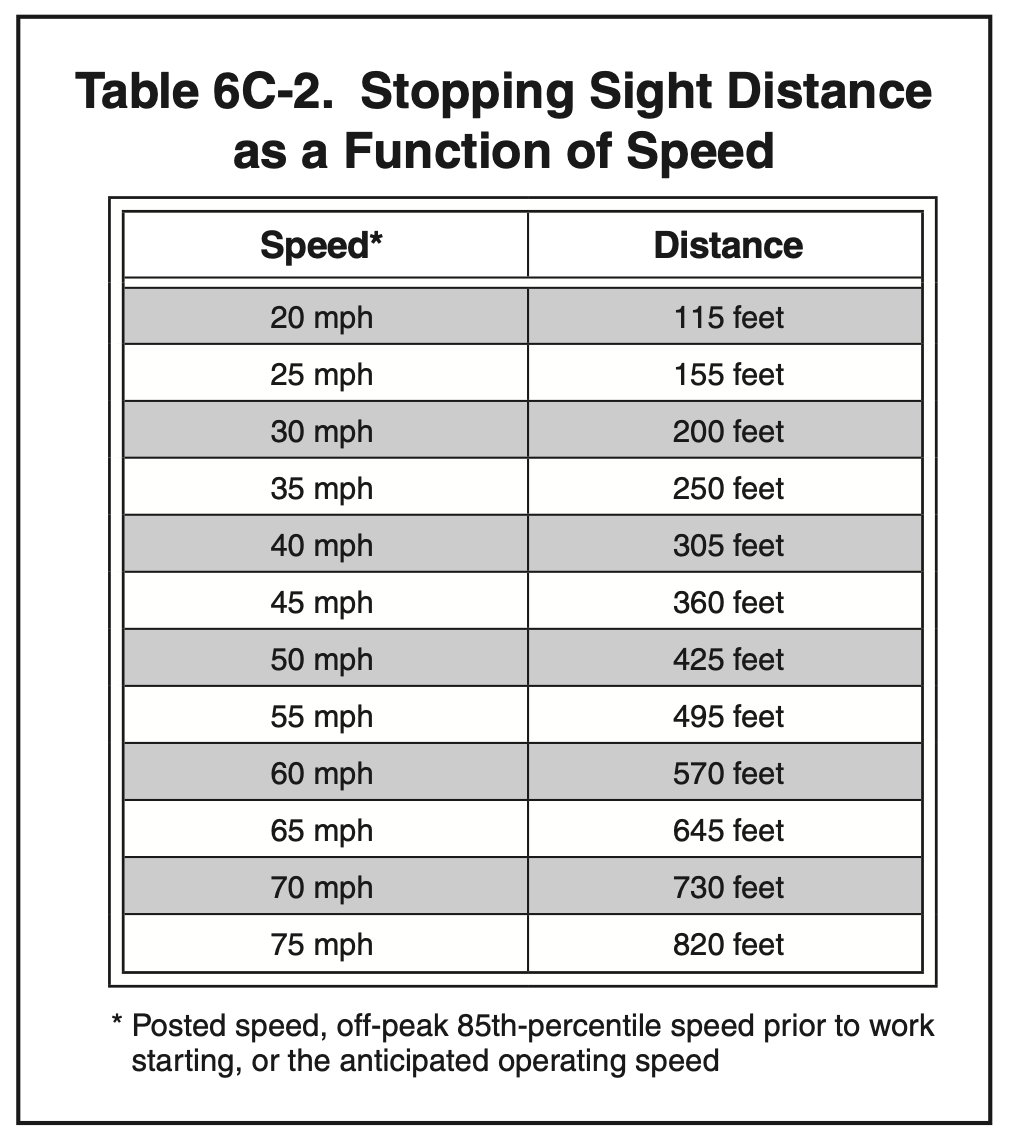

Distance Away and Speed of Approaching Driver – If an accident occurred due to a large truck pulling into or across traffic, it is important to know how many feet away the approaching vehicle was from the impact point and how fast the driver was traveling at that point in time. This information, along with an analysis of the retro reflective tape on the truck allows an assessment to be made as to how much time the driver had to identify the truck and take evasive action, and how many feet they had to do so. Combining this data with information about the condition of the retro reflective tape affixed to the truck allows us to make assumptions about what the driver saw, when they saw it, and how much time they had to react.

![]()