What standards must a retro reflective tape must meet to be certified?

The standards and specifications for DOT tape to be certified are required by Federal Regulation § 393.11, through its cross reference to FMVSS No. 108. I have included some definitions below which include agencies involved in the regulation of over the road trucks. There are quite a few and what each does can be a bit confusing. Also add to this that each state has its own Department of Transportation with rules and regulation.

The information and regulations below cover the color and pattern of the films that can be used as DOT tape, as well as the required photometrics. Also covered in the text below is the required placement of the DOT tape on the truck and trailer. For placement, this article is more clear and concise.

Definitions –

FMVSS – Federal Motor Vehicle Safety Standards

NHTSA – National Highway Traffic Safety Administration

FMCSA – Federal Motor Carrier Safety Administration

DOT – US Department of Transportation

Retro Reflectivity – the ability of an object to reflect light back to its source.

Conspicuity – something being highly visible or conspicuous. The process of making something more visible.

Photometry (photometrics) – science that deals with the measurement and intensity of light.

Certification – the process of assuring something meets certain standards.

Retro-reflector – a device used to indicate the presence of a vehicle by the reflection of light emanating from a light source not connected to the vehicle (similar to retro reflective sheeting)

§ 393.11 Lamps and reflective devices.

(1) Lamps and reflex reflectors. Table 1 specifies the requirements for lamps, reflective devices and associated equipment by the type of commercial motor vehicle. The diagrams in this section illustrate the position of the lamps, reflective devices and associated equipment specified in Table 1. All commercial motor vehicles manufactured on or after December 25, 1968, must, at a minimum, meet the applicable requirements of 49 CFR 571.108 (FMVSS No. 108) in effect at the time of manufacture of the vehicle. Commercial motor vehicles manufactured before December 25, 1968, must, at a minimum, meet the requirements of subpart B of part 393 in effect at the time of manufacture.

(2) Exceptions: Pole trailers and trailer converter dollies must meet the part 393 requirements for lamps, reflective devices and electrical equipment in effect at the time of manufacture. Trailers which are equipped with conspicuity material which meets the requirements of § 393.11(b) are not required to be equipped with the reflex reflectors listed in Table 1 if—

(i) The conspicuity material is placed at the locations where reflex reflectors are required by Table 1; and

(ii) The conspicuity material when installed on the motor vehicle meets the visibility requirements for the reflex reflectors.

(b) Conspicuity Systems. Each trailer of 2,032 mm (80 inches) or more overall width, and with a GVWR over 4,536 kg (10,000 pounds), manufactured on or after December 1, 1993, except pole trailers and trailers designed exclusively for living or office use, shall be equipped with either retroreflective sheeting that meets the requirements of FMVSS No. 108 (S5.7.1), reflex reflectors that meet the requirements FMVSS No. 108 (S5.7.2), or a combination of retroreflective sheeting and reflex reflectors that meet the requirements of FMVSS No. 108 (S5.7.3). The conspicuity system shall be installed and located as specified in FMVSS No. 108 [S5.7.1.4 (for retroreflective sheeting), S5.7.2.2 (for reflex reflectors), S5.7.3 (for a combination of sheeting and reflectors)] and have certification and markings as required by S5.7.1.5 (for retroreflective tape) and S5.7.2.3 (for reflex reflectors).

Federal Motor Vehicle Safety Standards (FMVSS) – Title 49 / Sub Title B / Chapter 5 / Part 571 / Sub Part B / 571.108 – Conspicuity Systems

(§ 571.108 Standard No. 108; Lamps, reflective devices, and associated equipment.)

S8.2 Conspicuity systems. The requirement for conspicuity systems may be met with retroreflective sheeting, conspicuity reflex reflectors, or a combination of retroreflective sheeting and conspicuity reflex reflectors.

S8.2.1 Retroreflective sheeting.

S8.2.1.1 Retroreflective sheeting must consist of a smooth, flat, transparent exterior film with retroreflective elements embedded or suspended beneath the film so as to form a non-exposed retroreflective optical system.

S8.2.1.2 Retroreflective sheeting material. Retroreflective sheeting must meet the requirements, except photometry, of ASTM D 4956–90 (incorporated by reference, see § 571.5) for Type V Sheeting. Sheeting of Grade DOT–C2 of no less than 50 mm wide, Grade DOT–C3 of no less than 75 mm wide, or Grade DOT–C4 of no less than 100 mm wide may be used.

S8.2.1.3 Certification marking. The letters DOT–C2, DOT–C3, or DOT–C4, as appropriate, constituting a certification that the retroreflective sheeting conforms to the requirements of this standard, must appear at least once on the exposed surface of each white or red segment of retroreflective sheeting, and at least once every 300 mm on retroreflective sheeting that is white only. The characters must be not less than 3 mm high, and must be permanently stamped, etched, molded, or printed in indelible ink.

S8.2.1.4 Application pattern.

S8.2.1.4.1 Alternating red and white materials.

S8.2.1.4.1.1 As shown in Figures 12–1 and 12–2, where alternating material is installed, except for a segment that is trimmed to clear obstructions, or lengthened to provide red sheeting near red lamps, alternating material must be installed with each white and red segment having a length of 300 ±150 mm.

S8.2.1.4.1.2 Neither white nor red sheeting must represent more than two thirds the aggregate of any continuous strip marking the width of a trailer, or any continuous or broken strip marking its length.

S8.2.1.5 Application location. Conspicuity systems need not be installed, as illustrated in Figure 12–2, on discontinuous surfaces such as outside ribs, stake post pickets on platform trailers, and external protruding beams, or to items of equipment such as door hinges and lamp bodies on trailers and body joints, stiffening beads, drip rails, and rolled surfaces on truck tractors.

S8.2.1.6 Application spacing. As illustrated in Figure 12–2, the edge of any white sheeting must not be located closer than 75 mm to the edge of the luminous lens area of any red or amber lamp that is required by this standard. The edge of any red sheeting must not be located closer than 75 mm to the edge of the luminous lens area of any amber lamp that is required by this standard.

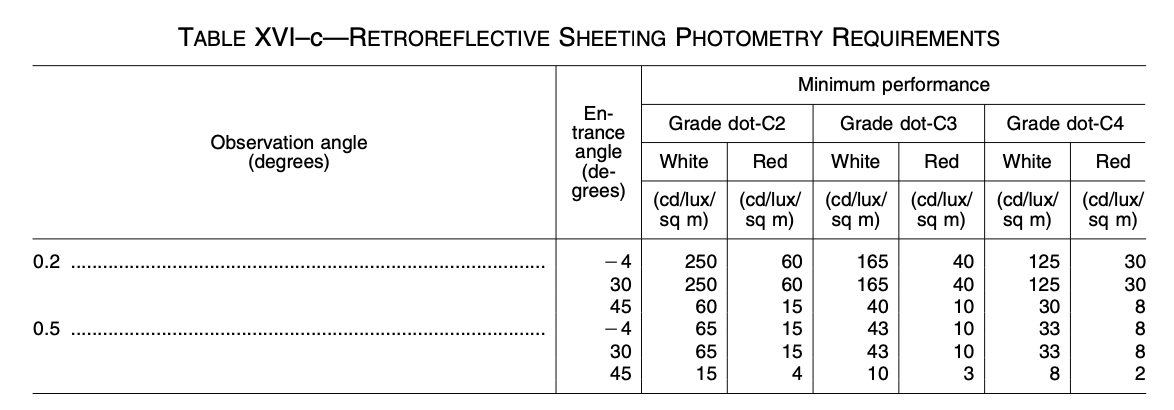

S8.2.1.7 Photometry. Each retroreflective sheeting must be designed to conform to the photometry requirements of Table XVI–c when tested according to the procedure of S14.2.3 for the color and grade as specified by this section.

S8.2.2 Conspicuity reflex reflectors.

S8.2.2.1 Certification marking. The exposed surface of each conspicuity reflex reflector must be marked with the letters DOT–C which constitutes a certification that the reflector conforms to the conspicuity reflex reflector requirements of this standard. The certification must be not less than 3 mm high, and must be permanently stamped, etched, molded, or printed in indelible ink.

S8.2.2.2 Application pattern.

S8.2.2.2.1 Alternating red and white materials. Conspicuity reflex reflectors must be installed in a repetitive pattern of two or three white reflectors alternating with two or three red reflectors, with the center of each reflector not more than 100 mm from the center of each adjacent reflector.

S8.2.2.2.2 White material. White conspicuity reflex reflectors must be installed with the center of each reflector not more than 100 mm from the center of each adjacent reflector.

S8.2.2.3 Photometry. – see also chart at bottom of this page for photometrics

S8.2.2.3.1 Each red conspicuity reflex reflector must be designed to conform to the photometry requirements of Table XVI–a for a red reflex reflector and Table XVI–b for a red conspicuity reflex reflector when tested according to the procedure of S14.2.3 as specified by this section.

S8.2.2.3.2 Each white conspicuity reflex reflector installed in only a horizontal orientation must be designed to conform to the photometry requirements of Table XVI–a for a white reflex reflector and Table XVI–b for a white horizontal conspicuity reflex reflector when tested according to the procedure of S14.2.3 as specified by this section.

S8.2.2.3.3 Each white conspicuity reflex reflector installed in a vertical orientation must be designed to conform to the photometry requirements of Table XVI–a for a white reflex reflector, and Table XVI–b for a white horizontal conspicuity reflex reflector and a white vertical conspicuity reflex reflector when tested according to the procedure of S14.2.3 as specified by this section.

S8.2.3 Conspicuity system installation on trailers.

S8.2.3.1 Trailer rear.

S8.2.3.1.1 Element 1—alternating red and white materials. As shown in Figure 11, a strip of sheeting or conspicuity reflex reflectors, as horizontal as practicable, must be applied across the full width of the trailer, as close to the extreme edges as practicable, and as close as practicable to not less than 375 mm and not more than 1525 mm above the road surface at the strip centerline with the trailer at curb weight.

S8.2.3.1.2 Element 2—white. (not required for container chassis or for platform trailers without bulkheads).

S8.2.3.1.2.1 As shown in Figure 11, two pairs of strips of sheeting or conspicuity reflex reflectors, each pair consisting of strips 300 mm long of Grade DOT–C2, DOT–C3, or DOT–C4, must be applied horizontally and vertically to the right and left upper contours of the body, as viewed from the rear, as close to the top of the trailer and as far apart as practicable.

S8.2.3.1.2.2 If the perimeter of the body, as viewed from the rear, is other than rectangular, the strips may be applied along the perimeter, as close as practicable to the uppermost and outermost areas of the rear of the body on the left and right sides.

S8.2.3.1.3 Element 3—alternating red and white materials. (not required for trailers without underride protection devices).

S8.2.3.1.3.1 As shown in Figure 11, a strip of Grade DOT–C2 sheeting no less than 38 mm wide or reflectors must be applied across the full width of the horizontal member of the rear underride protection device.

S8.2.3.2 Trailer side—alternating red and white materials.

S8.2.3.2.1 As shown in Figure 11, a strip of sheeting or conspicuity reflex reflectors must be applied to each side, as horizontal as practicable, originating and terminating as close to the front and rear as practicable, as close as practicable to not less than 375 mm and not more than 1525 mm above the road surface at the strip centerline at curb weight, except that at the location chosen the strip must not be obscured in whole or in part by other motor vehicle equipment or trailer cargo.

S8.2.3.2.2 The strip need not be continuous as long as not less than half the length of the trailer is covered and the spaces are distributed as evenly as practicable.

S8.2.3.2.3 If necessary to clear rivet heads or other similar obstructions, Grade DOT–C2 sheeting may be separated into two 25 mm wide strips of the same length and color, separated by a space of not more than 25 mm and used in place of the retroreflective sheeting that would otherwise be applied.

S8.2.4 Conspicuity system installation on truck tractors.

S8.2.4.1 Element 1—alternating red and white materials. As shown in Figure 13, two strips of sheeting or conspicuity reflex reflectors, each not less than 600 mm long, located as close as practicable to the edges of the rear fenders, mudflaps, or the mudflap support brackets, must be applied to mark the width of the truck tractor.

S8.2.4.1.1 The strips must be mounted as horizontal as practicable, in a vertical plane facing the rear, on the rear fenders, on the mudflap support brackets, on plates attached to the mudflap support brackets, or on the mudflaps.

S8.2.4.1.2 Strips on mudflaps must be mounted not lower than 300 mm below the upper horizontal edge of the mudflap. If the vehicle is certified with temporary mudflap support brackets, the strips must be mounted on the mudflaps or on plates transferable to permanent mudflap support brackets.

S8.2.4.1.3 For a truck tractor without mudflaps, the strips may be mounted outboard of the frame on brackets behind the rear axle or on brackets ahead of the rear axle and above the top of the rear tires at unladen vehicle height, or they may be mounted directly or indirectly to the back of the cab as close to the outer edges as practicable, above the top of the tires, and not more than 1525 mm above the road surface at unladen vehicle height.

S8.2.4.1.4 If the strips are mounted on the back of the cab, no more than 25% of their cumulative area may be obscured by vehicle equipment as determined in a rear orthogonal view.

S8.2.4.2 Element 2—white. As shown in Figure 13, two pairs of strips of sheeting or conspicuity reflex reflectors, each pair consisting of strips 300 mm long, must be applied horizontally and vertically as practicable to the right and left upper contours of the cab, as close to the top of the cab and as far apart as practicable.

S8.2.4.2.1 No more than 25% of their cumulative area may be obscured by vehicle equipment as determined in a rear orthogonal view.

S8.2.4.2.2 If one pair must be relocated to avoid obscuration by vehicle equipment, the other pair may be relocated in order to be mounted symmetrically.

S8.2.4.2.3 If the rear window is so large as to occupy all the practicable space, the material may be attached to the edge of the window itself.

S14.2.3 Reflex reflector and retroreflective sheeting photometry.

S14.2.3.8.2 Retroreflective sheeting. The required measurement for retroreflective sheeting reflectors at each test point as shown in Table XVI is candela per lux per square meter of area.

S14.2.3.7 Procedure. Photometric measurements of reflex reflectors and retroreflective sheeting must be made at various observation and entrance angles as shown in Table XVI.

![]()